Xiamen LFT Composite Plastic Co., Ltd. specializes in the production and sales of PBT. The color is long and durable.Long glass fiber with PBTPoly(butylene terephthalate) PBT reinforced ThermoplasticsSuitable for automobiles, such as fenders, electronic products, electrical appliances, handles, housings, etc., industrial parts, lampshades, etc. Poly(butylene terephthalate) PBT reinforced Thermoplastics

Xiamen LFT Composite Plastic Co., Ltd. specializes in the production and sales of PBT. The color is long and durable.Long glass fiber with PBTPoly(butylene terephthalate) PBT reinforced ThermoplasticsSuitable for automobiles, such as fenders, electronic products, electrical appliances, handles, housings, etc., industrial parts, lampshades, etc. Poly(butylene terephthalate) PBT reinforced Thermoplastics

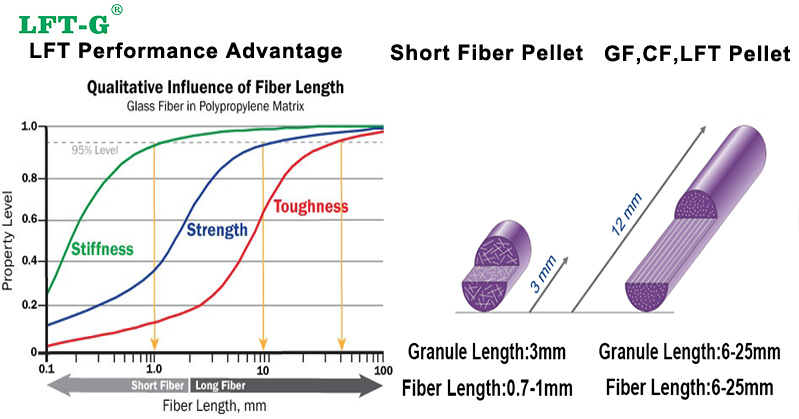

PBT was originally developed by German scientist P. Schlack in 1942. The company was then developed at Celanese Industrial and listed under the trade name Celanex. In the 1970s, Eastman introduced plexiglass reinforced chains and non-reinforced products. Subsequently, Germany BASE, the United States GE, Japan Toray, etc. have been put into production. As the amount of PBT resin on the market continues to increase, the flame retardancy of ordinary modified PBT materials is poor, the heat distortion temperature is not high enough, and the defects such as insufficient notched impact strength are more obvious. In order to make up for the shortcomings, the application field has been broadened. Relevant professionals at home and abroad are constantly changing. At present, domestic PBT modification mainly includes glass fiber reinforced flame retardant modified blend alloy modification. Since long glass fibers and PBT resins have good adhesive strength, Poly(butylene terephthalate) PBT reinforced Thermoplasticsare added to PBT. Adding a certain amount of long glass fiber to the PBTresin not only maintains the chemical resistance and processability of the PBT resin.As the original advantages, it can have a greater degree of mechanical performance improvement and overcome the sensitivity of the PBT resingap. The proportion of long glass fibers is different and the application fields are different.

General supplier

General supplier

Facebook

Facebook  Twitter

Twitter  Linkedin

Linkedin  YouTube

YouTube  Blogger

Blogger  Instagram

Instagram